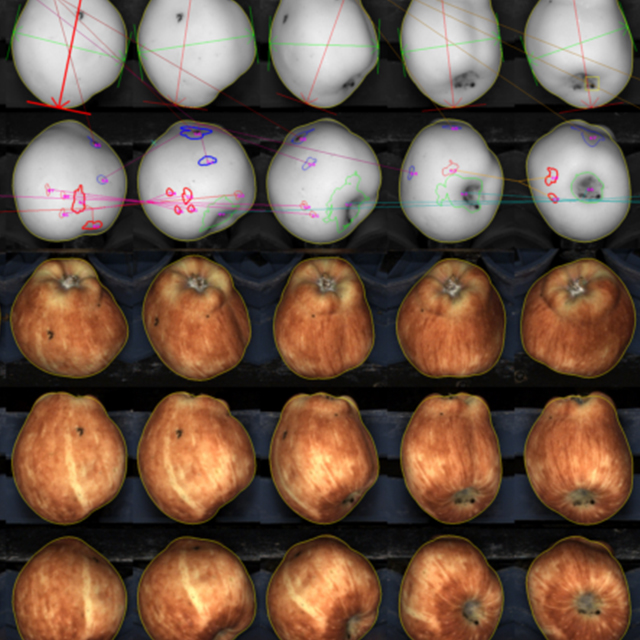

Deep AI learning

Our deep learning software called True-AI, gives you near-perfect grading accuracy and helps to detect complex defects. It also automates many of the operator’s tasks making their work life easier and leaving more time for other important issues.